120T Scalping Screen

Small Footprint, Big Value.

Don’t let the 120T Scalping Screen’s compact dimensions fool you, this mighty machine packs a lot of value into its small size.

The 120T passes material from its 8-yard feed hopper across two 12’ x 4’ screening decks to separate material into three fractions, and its simple design makes it rugged and low-maintenance – perfect for a growing processing operation.

Its heavy-duty tracks allow the 120T Scalping Screen to handle challenging environments and it’ll make your light aggregate, compost, recycling, topsoil, mulch, and wood chip processing a breeze!

Ready to upgrade to a processing powerhouse? Meet the EcoScreen 120T Scalping Screen.

Product Features

TIER-4 CAT ENGINE

Save fuel and enjoy longer run times with the state-of-the-art EPA-compliant Tier-4 CAT engine.

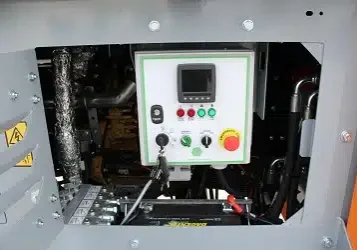

CENTRAL CONTROL PANEL

Easy operation, precise adjustments, and machine data accessible from the multifunctional display.

HEAVY DUTY TRACKS

Heavy-duty Strickland tracks easily maneuver over the most challenging terrain.

HYDRAULIC FOLD

All belts are designed to hydraulically fold for quick setup and transport.

FEED HOPPER

Generous 7.8 cubic yd hopper accepts a wide range of screen media from loaders or crushers.

SCREENING BOX

An area of 12’ x 4.2’ on both decks lets you easily process topsoil, mulch, compost, sand & gravel, aggregates and more.

CONVEYORS

Fines: 48” wide with a discharge height of 8.5’. Mids: 30” wide with a discharge height of 8.5’. Overs: 55” wide with a discharge height of 10.3’.

SIMPLE OPERATION

Self-controlled safety shutdowns and E-stops located around the machine.

120T SCALPING SCREEN Demonstration

Interested in the EcoScreen 120T Scalping Screen? Contact us to arrange an on-site demonstration at your facility, running your material, to see just how good it is!

Case Studies

Double O Organics Diverts Food Waste and Feeds the Earth with Tiger

Double O Organics is a Monett, Missouri based environmental services company that is passionately devoted to helping create a more sustainable future. One way it does so is by helping…

Read MoreCasco Is More Than a Landfill With Ecoverse

58 years ago In South Houston, TX, Noah Martini’s grandfather, R. H Martini, opened and operated a sandpit. After the sand was depleted he converted the property to a construction…

Read MoreRenewed Earth Accomplishes More With Doppstadt

Jake and Theresa Glas founded Kalamazoo Landscape Supplies in their basement, with just a phone number and a small fleet of trucks. Their business would grow significantly in the ensuing years, and…

Read More