A60 and A65 Compost Turner

Maximum Performance. Minimum Fuel Consumption.

The BACKHUS® A60 and A65 windrow turners provide maximum homogenization and oxygenation with its large diameter, high-torque, slow-speed drum that gets to the bottom of the windrow, every time.

The A60 can turn up to 6,500 yards per hour and handle windrows up to 20’ wide and 9’ tall, while the A65 can also turn 6,500 yards per hour while handling windrows up to 21’ 4” wide and 10” tall.

This high-capacity throughput coupled with the most fuel-efficient performance in the industry put BACKHUS compost turners in a class of their own.

Have challenges? BACKHUS A60 and A65 compost turners solve them.

Product Features

Easy Access

All critical components and functions of the machine are easily accessibly for routine maintenance and service.

INTUITIVE CONTROLS

Control operating speed and steering with one hand, and access critical functions via “top hat” push buttons on the intuitive joystick control.

PANORAMIC CABIN

The panoramic cabin and rearview camera provide clear visibility of the turning environment.

EFFICIENT ENGINE

BACKHUS makes the most efficient turners in the industry, and the standard diesel engine with turbocharger allows for maximum power.

HYDRAULIC TAILGATE

This operator-controlled feature manipulates the throwing of material and allows for the shaping of windrows or help with mixing.

POWERFUL DRIVETRAIN

The robust hydraulics system ensures the drum and drive handle the toughest material environments.

TRACK CLEARERS/PLOWS

Operating independently of the frame and drum position, the clearers are very easily controlled to provide toe-to-toe windrow placement. The one-touch ‘float’ feature maintains constant contact with the pad.

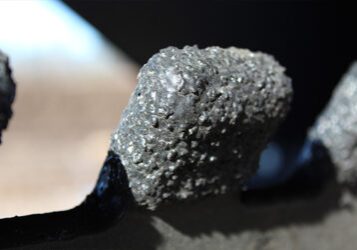

ARMORED DRUM TOOLS

The drum tools are coated with an abrasion-resistant material for maximum tool life.

A60 and A65 Compost Turner Demonstration

Interested in the BACKHUS A60 or A65 Compost Turner? Contact us to arrange an on-site demonstration at your facility, running your material, to see just how good it is!

Case Studies

380 McKinney Landfill Boosts Their Volume With the INVENTHOR 9

David Dugger had a problem. As the General Manager of the new 380 McKinney Landfill in McKinney, Texas, he was receiving anywhere from 700 – 1,000 tons of bulky construction…

Royal Oak Farm Doubles Down on Backhus, Doppstadt

Ken Newman began his journey as co-founder of Royal Oak Farm in England, his birthplace, and where he obtained a horticulture degree from City and Guilds of London Institute. After…

Sustainability in Colorado with A1 Organics & Ecoverse

The words “divert” and “sustainable” explain A1 Organics’ business in the simplest of terms: they divert organic waste from landfills to create compost, soil blends and mulch, resulting in a…