3-Fraction Star Screen

The Ultimate Screening Flexibility.

Produce three value-added products from just one single material stream with a Backers 3-fraction star screen. The Backers 3-fraction star screen generates huge volumes of precisely screened material at a very low cost per hour.

First, material is fed into the hopper where it moves across the screening deck by rotating stars. The material is loosened by the stars on the coarse deck, passing the midsize and fine fractions to the second deck, while the oversize is discharged off the front. The medium and fine particles are screened again on the lower deck, with each of the final fractions being discharged off the side and rear of the machine. Single pass, three products!

Wet and sticky isn’t tricky with Backers!

Product Features

OPTIONAL WIND SIFTER

Remove paper, plastic, and other light-fraction contaminants from the screening deck with an optional wind sifter.

DECK CLEANING SYSTEM

For the most challenging screening, the intelligent automatic cleaning system engages only when needed.

HIGH-PERFORMANCE SCREENING

Material is loosened before feeding to the fines deck for more effective and consistent fines screening.

MODULAR DECKS

The star screen deck is fully modular and interchangeable in 30 minutes, allowing for quick deck changes or star replacements.

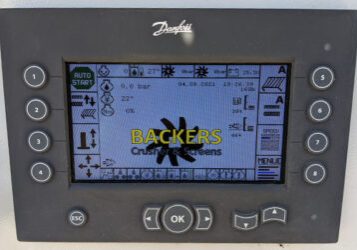

CAN BUS CONTROL SYSTEM

Complete monitoring and programming of all working functions are accessible through the CAN bus system.

ACCESSIBLE AND OPEN DESIGN

Open access to the screening deck allows the operator to see the entire process, giving the ability to fine-tune the machine.

3-Fraction Star Screen Demonstration

Interested in the Backers 3-fraction star screen? Contact us to arrange an on-site demonstration at your facility, running your material, to see just how good it is!

Case Studies

Renewed Earth Accomplishes More With Doppstadt

Jake and Theresa Glas founded Kalamazoo Landscape Supplies in their basement, with just a phone number and a small fleet of trucks. Their business would grow significantly in the ensuing years, and…

Kurtz Bros. Bring Consistency, Increase Volume With Backers Star Screen.

Kurtz Bros., Inc. has been a stalwart in Ohio for decades. Founded in 1948, they are best known for their mulch, topsoil and compost production, although they also offer various…

Production Up, Costs Down in Richland, Washington

The waste never stops at the Horn Rapids Landfill in Richland, Washington. Tracy Reed, the lead operator for the City of Richland, found that his processing equipment was stopping, however.…