Trommel Screen Drums: Everything You Need to Know

A trommel, sometimes called a drum screener or rotary screener, is a machine that features a rotating cylinder that separates material by size. The cylinder is perforated so that only material of a specified size falls through. Trommel screens are important tools in the recycling and organics processing industries and can be used for separating the biodegradable parts of mixed municipal waste or sizing compost, mulch, or crushed aggregate.

What are trommel screens used for?

Trommels are versatile machines that can separate a wide range of materials, including;

- Topsoil

- Compost

- Mulch

- Wood chips

- Sand

- Municipal solid waste

How does a trommel separate materials?

A trommel features a rotating drum, with bars or augers running inside the length of the drum to transfer material the length of the drum. As the drum spins, material is picked up and dropped back down to break it up into smaller pieces as it tumbles through the drum. This process is repeated until the material is small enough to fall through the screen and be discharged as fines, or until larger pieces that can’t be broken up exit the end of the drum to be discharged as overs.

There are two types of trommel screen designs: flat and gravity-fed.

Flat trommel drum screens include an internal auger or spiral that moves the material through the drum. A flat design lets owners easily swap out a drum with a loader in about 15 minutes and lets users quickly switch between processing different sized materials. Plus, they provide better material flow control to maximize throughput, and the load height is lower than inclined, gravity-fed trommels.

Inclined, gravity-fed trommel screens use a drum with replaceable screens to sort material. These machines are usually less expensive and individual screen sections can be replaced as needed, but the process typically takes several hours. Material throughput is lower than that of a flat trommel, and the load height is also higher.

The benefits of screening

Screening separates materials into different sized products. Most trommel screening machines produce two end-products: the desired sized product (as determined by the size of the drum openings), and the overs, most of which can be reground into a usable product or discarded.

Mulch is a good example to illustrate the benefits of screening. If a consumer purchased a large load of bulk mulch and it contained branches and large chunks, they’d be unsatisfied because the mulch wouldn’t be usable in their landscaping. They want uniformly sized pieces of wood that will help prevent weeds and retain moisture in their gardens, and look attractive. Proper screening can ensure a consistently sized product.

Now let’s cover trommel drum screens so you can understand what types are available and which you might need.

What’s going into the trommel?

It’s important to understand three aspects of the material you are separating: density, moisture content, and weight.

- Density. At their most basic level, trommels move material. Knowing the weight per cubic yard as it enters the trommel is crucial because it affects performance (it takes more power to move heavier material) and efficiency (it’ll take longer to process denser material).

- Moisture content. Excessive moisture will create sticky material, which tends to adhere to the drum or block the holes. Moisture also adds weight to the material and decreases screening efficiency.

- Weight. Material weight determines the screen thickness. A trommel drum separating crushed concrete will need a much thicker drum than one processing mulch or compost.

Next, what do you want to get out of the trommel? We’re not talking about what materials you want to separate, but what sort of production and efficiency do you need?

- Production. This is the rate of feedstock processed in a specific timeframe. Of course, trommel production varies widely based on the material being processed, the diameter and thickness of the drum, the size of the screen’s mesh size, and the speed of the rotation of the drum.

- Efficiency. The amount of time material spends in the trommel drum increases efficiency because it is turned over and over, breaking it up into small pieces that can fall through the screen. Screen area also matters, as does the shape of the drum’s holes because a square hole is larger and less uniform than the same sized round hole and will allow more material to pass through.

Keep in mind that production and efficiency may offset one another. Quickly pushing material through a drum may increase production (a lot goes in and comes out) but it may decrease efficiency (too many overs and not enough fines).

Features of trommel drum screens:

- Internal screw or auger. An internal screw will help material move through the drum and helps lift (and drop) material as the drum rotates.

- Lifter bars. These bars run the length of the drum and help in agitating and separating the material by providing the ‘lift and drop’ action that breaks larger pieces into smaller ones. It also helps material move through the drum, increasing production rate. Lifter bars are an integral part of skeletal drum configuration and an option on flat drum style trommels.

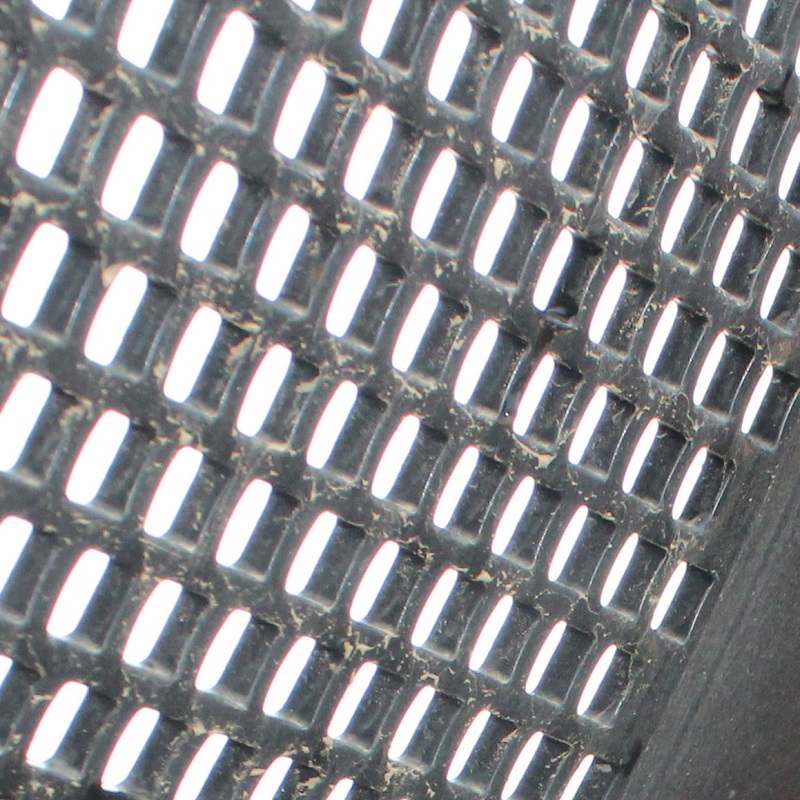

- Punch plate. Plates that are rolled and welded together to form the drum are stronger than a steel form with mesh attached and are less susceptible to damage from contaminants like steel and stones. Punch plates typically have a longer expected service life than mesh screens and produce a superior product shape and handle higher moisture material more efficiently.

- Plate thickness. The heavier the material, the heavier the plate should be, and thicker drums tend to last longer than thinner ones but can reduce throughput.

- Hole size and shape. Trommel drums are typically available in sizes from 3/8” to 3”. Square holes are larger in area than round holes and tend to agitate the material better, but this leads to additional cleaning required because they also get clogged more easily, especially when processing sticky, wet material.

- Cleaning brushes. Brushes help keep the trommel’s drum clean and clear of clogs so it can operate efficiently in its job of sorting and separating topsoil, mulch, aggregate, or compost.

- Bag rippers. Used to open bags and release their contents; commonly used in MSW and green waste collection applications and when growing media bags need to be opened so their soil contents can be screened.

There are also two other types of drums to consider for your organics processing operation: skeletal and solid.

A skeletal drum is just a framework to which mesh screens can be attached. A solid drum is just that, a drum with no holes. These are commonly used to add colorant to shredded and ground up wood to create a colored mulch product.

As you consider which trommel drum screen is right for your application, keep in mind that with so many variables impacting the process and final product, it’s important to work with a screening expert to sort out your needs. When you have questions, the environmental processing experts at Ecoverse can help you decide which drum is best for your operation or application. We can arrange a discovery call to learn about what you’re looking for and then set up a demo so you can see how a trommel can help your operation do more, better! Plus, we have all sorts of drums in stock and available for immediate delivery.

Ecoverse provides the best environmental and aggregate processing machinery to the North American market, including a complete lineup of machinery to help you transform waste into revenue. We’ve been selling the best engineered and made trommel screens for two decades, and we can help you do something amazing: create something from nothing by converting waste products into sellable goods. Plus, do it more efficiently or faster. Simply put, Ecoverse helps you do more things, and do them better so your operation can achieve unprecedented levels of production and profitability.

Want to learn how we can help your organization do more, better? Contact us!